Plastic wood material, also known as wood-plastic composite (WPC), is a revolutionary material that combines the natural beauty of wood with the durability and versatility of plastic. This composite material is made by blending wood fibers or flour with thermoplastics such as polyethylene, polypropylene, or PVC. Let’s delve into the world of plastic wood and explore its raw materials and diverse applications.

Raw Materials Used in Plastic Wood:

Wood Fibers or Flour: The primary component of plastic wood is wood fibers or flour derived from various sources. These can include recycled wood waste, sawdust, bamboo, rice husks, and even agricultural residues. These materials provide the natural aesthetics and unique grain patterns associated with wood.

Thermoplastic Polymers: The wood fibers are combined with thermoplastic polymers, typically polyethylene, polypropylene, or PVC. These polymers act as a binding agent, holding the wood fibers together and providing the composite with its durable and weather-resistant properties.

Applications of Plastic Wood Material:

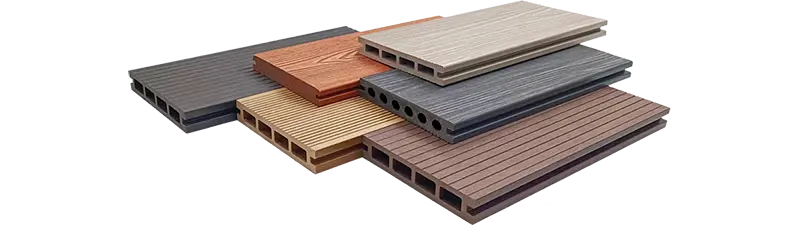

Decking and Outdoor Structures: Plastic wood is widely used for decking and outdoor structures such as pergolas, boardwalks, and patio furniture. It offers excellent resistance to rot, decay, and insect infestation, making it a durable and low-maintenance alternative to traditional wood.

Cladding and Siding: Plastic wood can be used as cladding or siding for buildings. Its resistance to moisture, UV rays, and harsh weather conditions ensures long-lasting protection and aesthetics.

Fencing and Landscaping: Plastic wood is an ideal material for fencing, as it is resistant to warping, splitting, and discoloration caused by weather exposure. It can also be used for landscaping applications like garden borders, retaining walls, and decorative elements.

Indoor Flooring: Plastic wood can be used as flooring material, particularly in areas where moisture is a concern, such as bathrooms, kitchens, and basements. It provides the look of hardwood while offering improved water resistance and durability.

Furniture: Plastic wood is utilized in the production of indoor and outdoor furniture. From chairs and tables to benches and picnic sets, it offers a durable, weather-resistant, and eco-friendly alternative to traditional wood furniture.

Automotive Applications: Plastic wood finds applications in the automotive industry, where it is used for interior trim, door panels, dashboard components, and other interior features. Its lightweight nature, durability, and resistance to fading make it a viable choice.

Packaging Materials: Plastic wood is increasingly being used in the manufacturing of packaging materials like crates, pallets, and shipping containers. Its strength, stability, and resistance to moisture make it suitable for these applications.