Plastic wood, also known as wood-plastic composite (WPC), is an innovative material that combines the natural aesthetics of wood with the durability and versatility of plastic. It is a composite material made from a mixture of wood fibers or flour and thermoplastics such as polyethylene, polypropylene, or PVC. This combination results in a material that exhibits the characteristics of both wood and plastic, offering a range of advantages and applications. Let’s delve deeper into the world of plastic wood:

Advantages of Plastic Wood Material:

- Durability: Plastic wood is highly durable and resistant to rot, decay, and insect infestation. Unlike traditional wood, it does not splinter or crack easily, making it suitable for various outdoor applications.

- Low Maintenance: Plastic wood requires minimal maintenance. It does not require staining, sealing, or painting like natural wood. Regular cleaning with water and mild soap is usually sufficient to keep it looking great.

- Moisture Resistance: Plastic wood is highly resistant to moisture, making it an excellent choice for environments exposed to water or high humidity. It does not warp, swell, or rot when exposed to moisture, ensuring long-term performance.

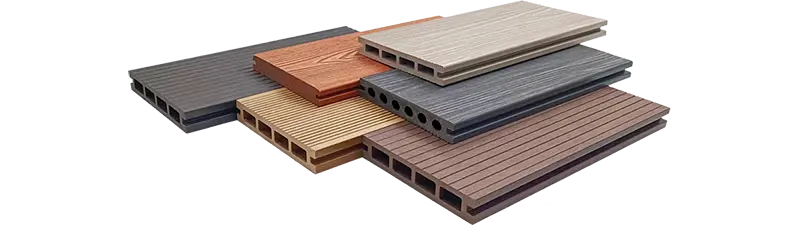

- Versatility: Plastic wood can be molded into various shapes and sizes, offering design flexibility for a wide range of applications. It can mimic the appearance of natural wood or have its own unique aesthetic, allowing for creative and customized designs.

- Environmentally Friendly: Plastic wood is often made from recycled materials, reducing the demand for virgin wood. It helps to conserve natural resources and reduce waste. Additionally, its long lifespan and low maintenance requirements contribute to sustainability.

Disadvantages of Plastic Wood Material:

- Heat Sensitivity: Plastic wood has a higher coefficient of thermal expansion than natural wood, meaning it expands and contracts more significantly with temperature changes. This can result in dimensional changes and potential warping if not properly installed or supported.

- Appearance: While plastic wood can resemble natural wood, it may not fully replicate the texture and grain patterns of real wood. Some people may prefer the authentic look and feel of natural wood.

- Color Fading: Over time, plastic wood may experience color fading or change due to exposure to sunlight. UV stabilizers can be added to mitigate this effect, but some level of color change may still occur.

Applications of Plastic Wood Material:

- Decking and Outdoor Structures: Plastic wood is commonly used for decking, railing, and other outdoor structures. Its durability and resistance to moisture make it ideal for withstanding weather elements.

- Fencing and Privacy Screens: Plastic wood can be used for fencing and privacy screens, providing a low-maintenance alternative to traditional wood options. It offers privacy, aesthetics, and longevity.

- Furniture: Plastic wood is used in the production of outdoor furniture such as chairs, tables, and benches. It provides a durable and weather-resistant option for creating comfortable and stylish outdoor seating.

- Landscaping: Plastic wood can be used for landscaping applications such as garden beds, pathways, and pergolas. Its resistance to moisture and insects makes it suitable for these outdoor installations.

- Interior Applications: Plastic wood can also be utilized indoors for applications such as wall paneling, flooring, and cabinetry. Its moisture resistance and low maintenance qualities are advantageous in areas prone to moisture, like bathrooms and kitchens.

Plastic wood material offers a compelling alternative to traditional wood, combining the natural aesthetics of wood with the durability and versatility of plastic. Its advantages, including durability, low maintenance, and moisture resistance, make it suitable for a wide range of applications in both outdoor and indoor settings.